How Is CBD Extracted?

Many people ask about the way we get CBD from the hemp plant. It’s good to know how CBD products are made, especially with so many different ones out there. One way to get CBD is by using hemp oil extractors. These machines help take out the CBD from the plant. There are a few different ways to do this, and we’ll talk about them here.Our Favorite Extraction Method

We like to use a method called hydrocarbon extraction. This means using gases like butane or propane to get the CBD out. Some people call this Butane Hash Oil or BHO. Fun fact, our Bluegrass Hemp Oil is also known as BHO! This method is good because it gets a lot of CBD out of the plant.Other Ways to Extract CBD

- CO2 Extraction: This way uses carbon dioxide under high pressure to get the CBD. C02 is popular in the THC market but for medical quality products such as full spectrum CBD oil it is not capable of producing the quality that BHO does.

- Ethanol Extraction: In this method, the plant is soaked in ethanol to get the CBD out. It’s a simple and effective way. This process also extracts unwanted parts that offer no benefits.

HYDROCARBON EXTRACTION

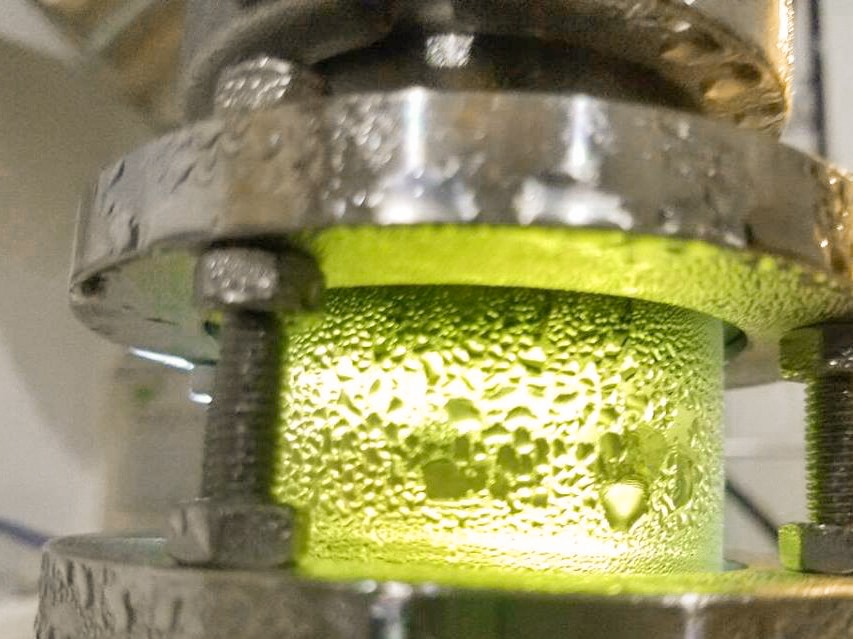

An article written by Lindsay Maharry, “Debunking the BHO Stigma: A Scientist’s Take on Butane Hash Oil vs. CO2 Extraction,” does an excellent job of shining a light on how unsafe practices engaged in by kids changed the perception of this extraction method. (I highly recommend you read it!) When in fact, this method, if done correctly, is completely safe. Hydrocarbons are non-polar, meaning they bind to the more fat-soluble components of the plant (cannabinoids and terpenes only) to extract compounds from cannabis plant material gently. The result is a higher-purity extract and the only product that resembles the plant from which it came. Butane and propane allow organic solvents to be used in an extraction process that produces the richest cannabinoids and terpenes. This oleoresin is live resin. The live resin extraction method makes high-quality cannabis oil like what we use for our Genesis Blend full spectrum CBD oil.

Learn about Bluegrass Hemp Oil’s BHO CBD

WHAT ARE HYDROCARBONS?

Hydrocarbons are a classification of organic compounds consisting of carbon and hydrogen, formed from the compression of animal and plant remains over long periods. The most common hydrocarbons include butane and propane. Hydrocarbons are also powerful organic solvents – substances capable of dissolving or dispersing other substances. They’re most commonly used in natural flavorings, soybean oil, vegetable oil, and many other food products consumed daily. It works well as butane has a low boiling point. That allows us to recover it at a low temperature in our extraction process. These preserve the most cannabinoids and terpenes.

Fun fact: Hydrocarbons like propane and butane are recognized as safe by the FDA and have been used since the 1970s for food production and extractions. Menu items like crème Brulee and flan are finished with a butane torch to crust them. Many will host barbeques while cooking their food with a propane grill. And let’s not forget the smokers who light up with butane lighters!

WHY BUTANE?

As we stated, butane allows our extraction process to recover it at a low temperature. These preserve the most cannabinoids and terpenes. Butane is a popular solvent in the cannabis world. It’s a non-polar, Class 2 liquefied gas with a low boiling point of 31.1°F and an evaporation point of 33°F. In cannabis extraction, this is important because it allows for the cold-boiling of any leftover solvent from the concentrate, preserving cannabinoids and temperature-sensitive terpenes, resulting in a high-quality product free from residual solvents. That other extraction process can not be achieved. Butane is GRAS by the FDA for food manufacturing. The process is used to make high quality oils such as MCT oil from coconut.

OTHER COMMON EXTRACTION METHODS

Co2: Co2 extraction is a process that uses pressurized carbon dioxide to pull desired cannabinoids from the plant. Its vapor pressure is so high the CO2 disappears, leaving no potential for residual. However, this pressure is harsher on the plants and strips the terpenes during the process. In Maharry’s article, she explains the appeal of this process to manufacturers in the industry, stating it allows companies “to get away with running poor quality flowers” because they are producing a homogenous product. (In her case, she focuses on THC only, whereas what we see in the hemp industry is CBD only.) This affects the over all quality of the CBD oil. If the cannabinoids do not get extracted during the extraction process, how can they end up in the final CBD Oil? They can’t. Some Co2 extraction machines look big and fancy but do not produce high-quality extract CBD oil.

Ethanol: In this process, the solvent, Ethanol, is passed over the plant material to dissolve the cannabinoids in the plant. Because ethanol is a “polar” solvent, it will want to bind to the water-soluble components of the plant. The result is a less pure, generally less potent, end product that needs further post-processing and refining. Therefore, it has limitations in making a genuinely pure, full-spectrum extract. Have we discussed we only want the significant lipids from the plant material? That is why the only plant matter we like to use is the bud or flower from the cannabis or hemp plants.

For a detailed comparison and insights on CO2 versus Solvent-Based Extraction methods, you can explore the informative video provided in this comprehensive guide on extraction techniques.

Visit our Podcast page and listen in as we discuss the most common methods of extraction in Episode 11

Understanding CBD Extraction Techniques for Optimal Purity and Effectiveness

How is CBD Extracted from Hemp?

Discover the meticulous process of extracting CBD, a compound renowned for its potential wellness benefits, from the hemp plant using various sophisticated methods.

Preferred Extraction Method: Hydrocarbon

Learn why Bluegrass Hemp Oil advocates for hydrocarbon extraction, utilizing butane and propane, to produce a rich, full-spectrum CBD oil, known for its purity and potency.

Exploring Various CBD Extraction Methods

- CO2 Extraction: A method that utilizes carbon dioxide under high pressure, often preferred for THC products, yet may not retain the quality required for full-spectrum CBD oil as effectively as hydrocarbon extraction.

- Ethanol Extraction: A simpler method that involves soaking the plant in ethanol, which may also extract non-beneficial components, emphasizing the importance of selectivity in extraction.

For a deeper understanding of these methods, consider reading more about common CBD extraction techniques.

Comprehensive Guide to Hydrocarbon Extraction

Delve into the specifics of hydrocarbon extraction and its advantages for yielding high-quality CBD oil, as featured in our podcast on extraction methods.

The Role of Hydrocarbons in Extraction

Hydrocarbons, consisting of carbon and hydrogen, are utilized as powerful solvents in the extraction process due to their ability to dissolve substances, making them integral to producing pure, potent CBD oil.

Why Butane is a Superior Solvent for CBD Extraction

Butane, a non-polar solvent with a low boiling point, is essential for preserving delicate cannabinoids and terpenes during extraction, resulting in a superior-quality product.

Other Common CBD Extraction Techniques

Compare CO2 and ethanol extraction methods, which have their own merits but may not achieve the same level of terpene preservation as hydrocarbon extraction.

Gain further insight from an expert analysis in the article “Debunking the BHO Stigma: A Scientist’s Take on BHO vs. CO2 Extraction.”